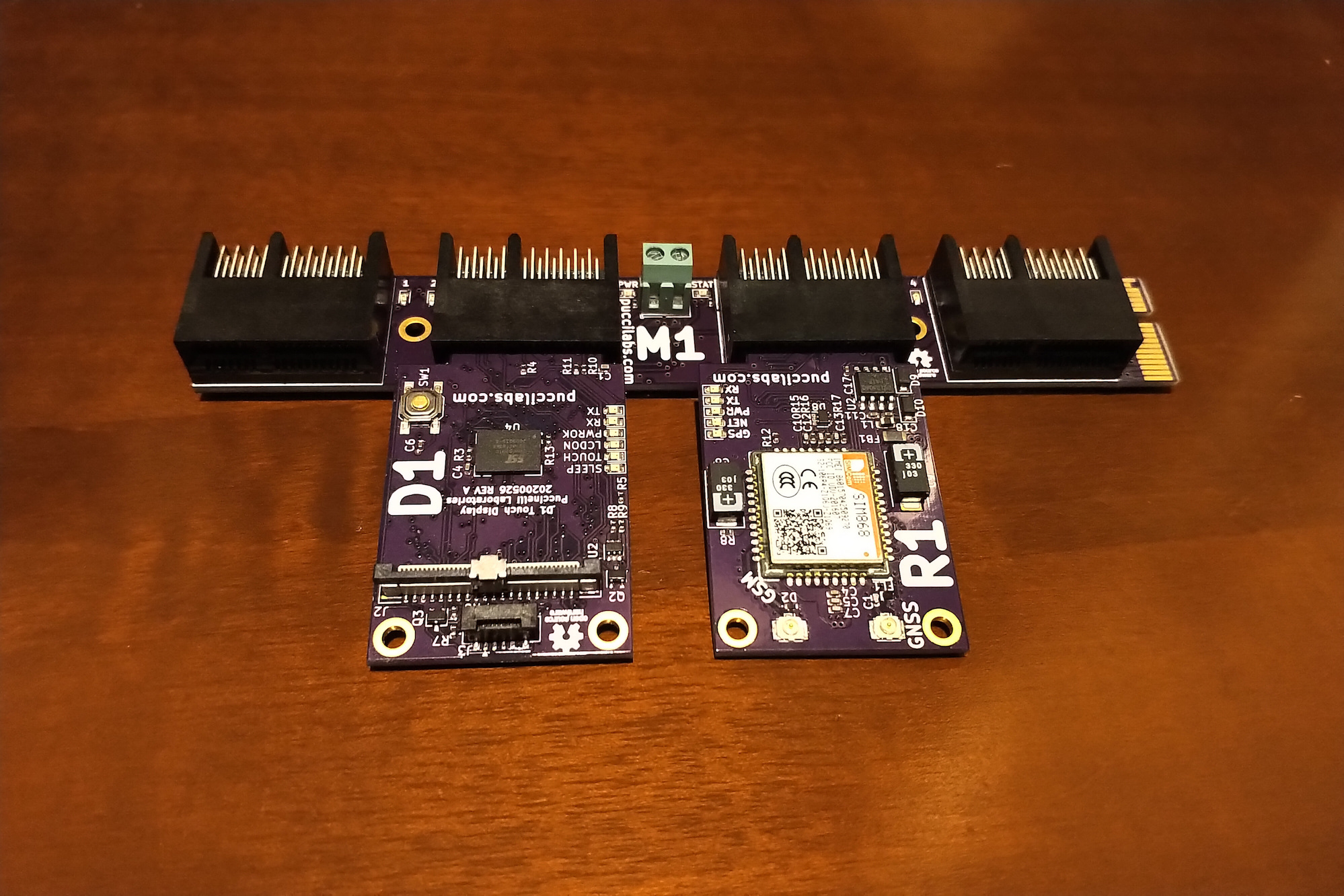

Vespucci System with M1, D1, and R1 Modules.

Vespucci System with M1, D1, and R1 Modules.

Overview

Although many promising diagnostic assays have been and continue to be produced in research settings, there are massive engineering and logistical barriers that hinder their deployment and evaluation in real world settings. The Vespucci system serves to streamline the transition between benchtop assay and in-field diagnostic.

This is made possible by relying on one key design principle: modularity.

Modularity

There are many situations where a modular solution has major advantages over a custom design. In addition to significantly reducing upfront engineering time and cost, it provides:

- the ability to reuse components in any design such as having a common touchscreen module,

- the ability to explore different designs for different environments such as using a WiFi module for local testing and switching to a 3G module for remote use in the field,

- the ability to repair damaged systems in the field easily with no major technical experience,

- the ability to upgrade systems at any time by simply replacing the module such as evaluating an higher sensitivity detection module for your assay.

Other Advantages

Although a modular solution will not be the most cost efficient approach when producing diagnostic systems by the thousands, it provides major cost savings before a design is ready to be produced at full scale.

The iteration speed of a custom solution is incredibly slow due to the need to design the circuits, develop the software, and produce the boards. If there is an aspect of the design that needs to be reworked, which could be simple like designing with the wrong part footprint or advanced like upgrading sensors, it can take several weeks to reiterate each time. Vespucci spares end users of a majority of these challenges by offering a suite of modules that have already been validated and deployed.

Cost savings have also been built into the board designs by making the board footprints as compact as reasonably possible while also minimizing the number of unique components used across all designs. Smaller board footprints allow more boards to be produced in a single run, which can lower the fabrication cost rather dramatically. Also, reducing the number of unique components across all designs not only reduces inventory costs as price per part drops exponentially with quantity, but it also aids in factory assembly of boards as each machine can fit a limited number of component reels. Production costs will also be low if all boards can be produced on one machine without needing to change component reels.

In regard to adoption and sharing designs, all modules utilize a modified PCIe interface that is standardize across all Vespucci boards. Anyone is able to design and share a module knowing that it will work for any system. This is particularly useful for teams that develop new assays and want to share improvements with their collaborators in the field or those who want to reuse old equipment. All Puccinelli Laboratories Vespucci boards are open source to allow the ecosystem to grow naturally.